Achieve exceptional results in 3D printing with the Wiiboox W600 Pro 3D Printer. Designed for both professionals and enthusiasts, this advanced printer combines cutting-edge technology with a user-friendly interface to deliver high-quality prints across a variety of materials. Whether you're working on prototyping, product design, or creative projects, the W600 Pro is your go-to solution for precision and reliability.

Key Features:

- High Precision Printing: The W600 Pro features advanced motion control technology that ensures accurate and consistent layer deposition, resulting in detailed and high-quality prints.

- Large Build Volume: With an expansive build area, the W600 Pro allows for the creation of larger models or multiple parts simultaneously, optimizing your workflow and productivity.

- Versatile Material Compatibility: This printer supports a wide range of materials, including PLA, ABS, PETG, TPU, and more, providing flexibility for various projects and applications.

- User-Friendly Interface: The intuitive touchscreen interface simplifies the printing process, making it easy for users of all skill levels to navigate and operate the printer efficiently.

- All-Metal Hotend: Equipped with a durable all-metal hotend, the W600 Pro can handle high-temperature materials, ensuring a wider range of filament compatibility and enhanced performance.

Why Choose Wiiboox W600 Pro 3D Printer?

- Reliable Performance: Built with high-quality components, the W600 Pro is designed for long-lasting performance, ensuring consistent results in every print.

- Easy Setup and Maintenance: The printer features a straightforward setup process and easy maintenance, allowing you to spend more time printing and less time troubleshooting.

- Compact and Stylish Design: With a sleek and compact design, the W600 Pro fits seamlessly into any workspace, making it an attractive addition to your studio or office.

The Wiiboox W600 Pro 3D printer is a large-format industrial FDM printer. It has a reinforced structure, a huge build area, and is capable of long-term printing without interruption. All this allows it to be used for full-scale production or for the release of complex prototypes.

Almost all the main components of this floor-standing FDM printer are manufactured according to industrial standards, including a rigid all-metal case. Inside there is a build area, completely protected from external influences, which is especially important when working with engineering materials such as ABS, ASA, PP, PC and others. The dimensions of the build area are 600x600x1000 mm.

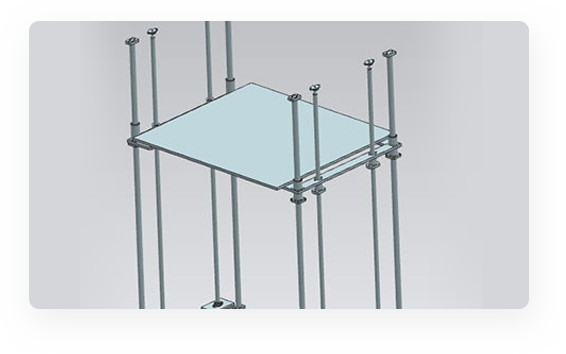

In order to improve the quality of printing large objects, a 4-screw lever mechanism on the Z axis was used in the design of the 3D printer. It makes the up-down movement as stable as possible, and the surface of the product during printing becomes smoother. Powerful mechanics and industrial-grade servo motors allow you to work with huge models weighing up to 80 kg.

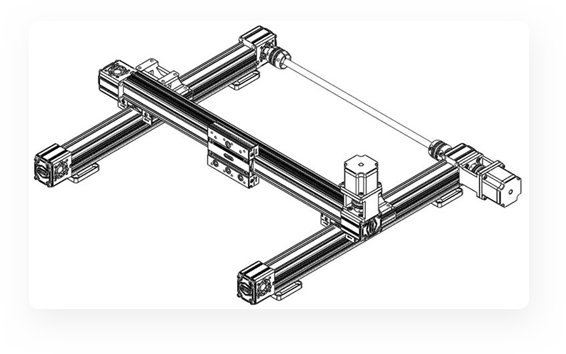

The XY axis adopts a dual-axis guide module. The use of industrial-grade dual-axis guide makes the print head movement quieter and more accurate. The maximum speed can reach 150 mm/s.

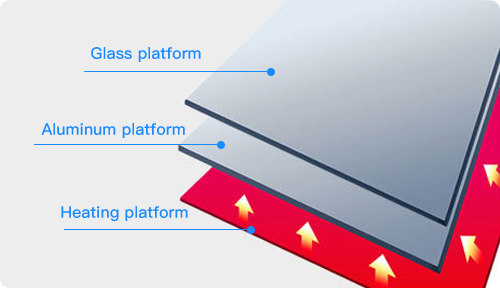

The Wiiboox W600 Pro 3D printer is equipped with one extruder with a maximum temperature of 260 degrees Celsius. The printing platform can heat up to 120 degrees. The durable platform design and special silicone coating effectively prevent warping, deformation and other common problems when printing using the FDM method.

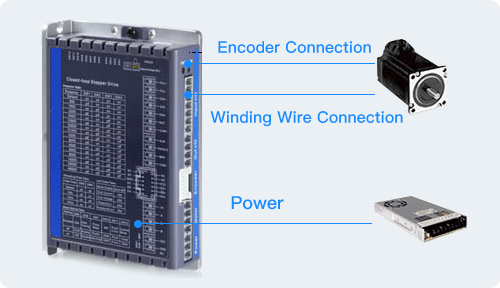

The printer adopts closed-loop control technology to ensure that there is no lost step when printing. The encoder is used as position feedback, and the stepper motor has the characteristics of a closed-loop servo. This helps compensate for position deviation in real time and fundamentally solves the problem of lost steps caused by the traditional stepper motor.

Wiiboox slicing software supports various user-friendly functions, including model repair, tunnel creation, cutting and size adjustment with a powerful algorithm. In addition, the slicer can automatically generate support and allows you to easily select preset printing parameters with one click. Model processing becomes easier and smarter.

7-inch color touchscreen, simple and convenient interface with numerous tips make working with the printer simple and convenient even for a novice user.

Closed-loop control technology, No lost steps in operation

The encoder is used as the position feedback, so that the stepper motor has servo closed-loop characteristics, which can compensate the position deviation in real time and fundamentally solve the problem of losing steps occurred in the traditional stepper motor.

4-screw linkage mechanism

The 4-screw linkage mechanism of the Z axis makes the up-and-down motion steady and firm, and the printing surface smoother, so that the giant model as heavy as 80kg can be printed out.

High-power silicone heat bed

Effectively prevent printing problems, such as warping and deformation.

Dual-axis guide module

The XY axis adopts dual-axis industrial-grade guide rail, which makes the printing motion quieter and preciser.

Technical Parameters W600 Pro

|

Compare products

{"one"=>"Select 2 or 3 items to compare", "other"=>"{{ count }} of 3 items selected"}